Spent a morning this week at Tuthill Porsche, watching a proper 3.0 911 RSR engine go together. The most interesting thing about this engine is it was built using rare factory sand-cast engine cases: something apart from the norm and a nice link to RSR heritage.

Richard Tuthill has always promised to help with a top end rebuild on my Carrera 3.0 engine, currently resting with tired valve guides and a cracked head stud. The C3 engine has much in common with the RSR motor, so there was plenty on this build that would also apply to my own. I’d seen these cases when they first arrived in the parts washer, so looked forward to watching them come back to life: it was going to be educational.

Engine builder Anthony served as Francis’ apprentice and has since built countless Porsche engines and transmissions, using a mix of Fran’s teachings and knowledge gleaned from other engine gurus. It will be a few years before he has the wrinkles to countenance his impressive store of knowledge, but no doubt he’s en route to the top of his field.

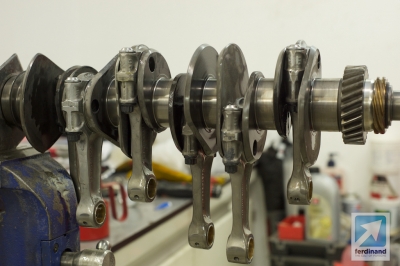

As you’d expect, this was not the first time the race engine had been stripped, and some bits needed a rethink. When the original crank was found to need oversize bearings at three grand a set from our German friend, it made more sense to keep the ancient crank safe, and prepare a new crankshaft to RSR spec.

The 6-bolt crankshaft was knife-edged, polished and nitrided (hardened in a 72-hour process) before being fitted with the original connecting rods. These were original and I thought quite lovely. Edges had been ground and polished before the rods were shot peened: nothing overly dressy. These engines are all about go, not show.

One illuminating job on the crankshaft assembly was stretching the rod bolts using a rod bolt stretch gauge. The bolts are at max clamp load when stretched by 10 thousandths of an inch, so Anthony’s junior held the ARP gauge while the bolts were stretched up to spec.

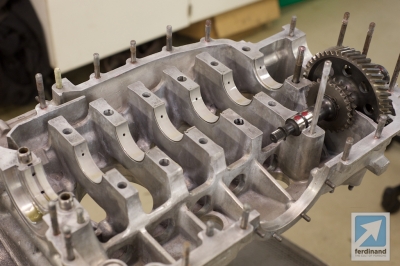

With the crankshaft assembled, the builder spent a long time cleaning and lubricating the first case half, installing oil seals, oil pump, timing chains and intermediate shaft before dropping the crank in, adding more seals, using a variety of sealants to prep the case further, then turning his attention to the other case half.

This was given the same close attention: lots of cleaning, lubrication and then a different sealant. When everything was ready, the case halves were joined together and Anthony worked quickly to get it all buttoned up while the sealant was curing. Next job was to install pistons and cylinders and measure the heights and CCs, so they could be sent off for finishing. More on that next time (it’s good).

Nice!

The best engine in the world.-

^This!

That is awesome

just amazing

I think it is good idea to share this here.-

Enjoy it!

http://youtu.be/st3WDUYomkk

genios!!

OMG. Good memories!

3.0L for a Carrera. Replaced my 2.7L

Gotta watch>

I Need it.

What satisfaction there must be in bringing an engine of that importance back to life Anthony is in an enviable position which has come about not by luck but because the apprenticeship he did gave him the chance to show he is a very capable man.Also great pictures would love to see more

Bob

Cool! Thanks for sharing!